03 February 2026

Artificial Intelligence (AI) has become one of the most talked about topics today. We find it everywhere, from smartphone apps to shopping suggestions, so much so that it is natural to wonder if it is truly as useful as everyone says. Yet, far from the media spotlight, AI has already proven its immense value within scientific research, often making it possible to tackle challenges that were previously unthinkable. This is particularly true for regenerative medicine and bioprinting, fields where complexity, precision, and a broad vision often represent obstacles too great for the human mind to handle alone.

Advanced algorithms are changing the rules of the game. Thanks to the power of these systems, bioprinting is moving from 3D production to 4D. But what does this actually mean? It means that the printed tissue does not remain static. Instead, it is designed to react and transform once inside the body. Essentially, it can adapt over time, which represents the fourth dimension. Predicting how cells will behave over months or years while managing a massive amount of data is beyond human capacity. AI steps in here, coordinating the process and ensuring that technology blends naturally with the flexibility and complexity of biology.

Let us look at some examples of how AI is rapidly transforming this field of research.

The choice of inks

The first major contribution of artificial intelligence concerns the preparation of biological inks, known as bioinks. Creating a tissue does not just mean arranging cells, but immersing them in materials that must be simultaneously printable and capable of sustaining life. Long before the printing starts, there is an extensive experimentation phase to find the most suitable bioinks. Traditionally, finding the perfect combination took years of trial and error.

Today, AI acts as a biochemist, analyzing thousands of possible mixtures and predicting which will guarantee the best structural stability and maximum cell survival. Advanced algorithms can predict the accuracy of the final shape or cell viability based on data such as air pressure or the concentration of chemical components. Predictive models can even find optimal printing parameters before the printer is even turned on. This drastically reduces research time and costs while allowing for the creation of customized biological structures.

Digital eyes on the printhead

Once printing begins, the focus shifts to real-time monitoring. The most common bioprinting techniques, such as those based on needle extrusion, are subject to many variables. Even a tiny change in pressure or temperature can ruin the final result. Here, AI becomes a real-time supervisor. Using advanced sensors and high-resolution cameras, the system monitors every second of the process.

If the algorithm detects a small imperfection, irregular material flow, or a nozzle clog, it intervenes instantly by adjusting the printing parameters. It can identify anomalies within milliseconds. This self-correction capability, known as closed-loop control, transforms a simple machine into an intelligent system capable of ensuring that every millimeter of tissue follows the original design. This level of autonomous control is fundamental to ensuring that every biological construct is identical to the last, a requirement that is essential for patient safety.

Post-printing quality control

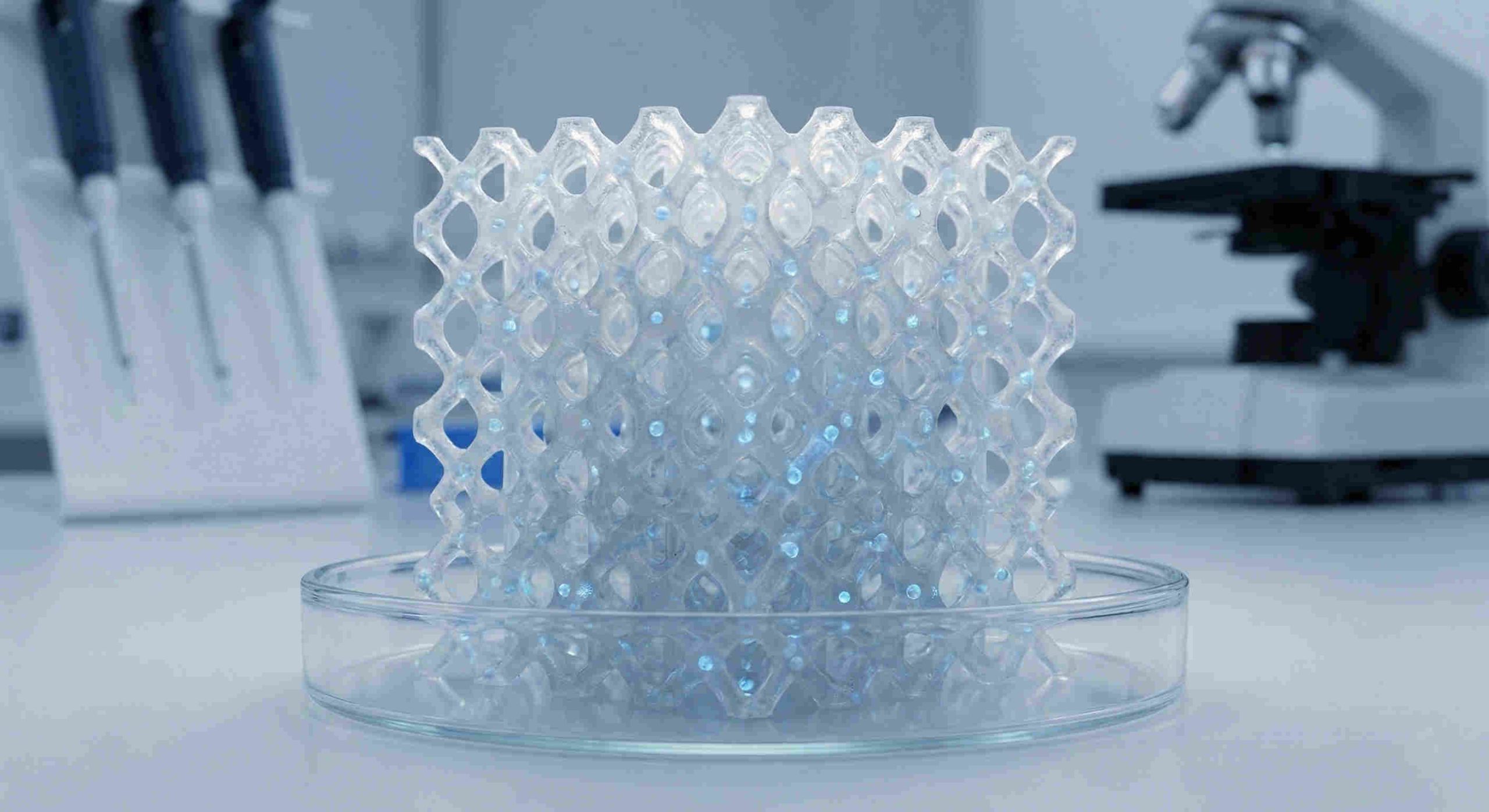

The work of AI does not end when the printer stops. It continues to operate during the post-processing phase. Evaluating whether a biological tissue is healthy and functional is an extremely complex task. Through advanced computer vision models, it is possible to analyze microscopic images to verify cell morphology and how cells multiply.

These systems identify patterns invisible to the human eye, ensuring the printed tissue has the biological properties needed for success. This type of automated analysis provides objective data on cell proliferation within the printed tissues, removing human subjectivity and mitigating the chance of error. At the same time, it allows for large-scale validation of the produced tissues with a significant reduction in analysis time.

Beyond bioprinting

Innovation does not stop at traditional 3D bioprinting. To create tissues that truly mimic human ones, they must be programmed to transform and adapt over time. This is the goal of 4D bioprinting, which paves the way for tissues with even more sophisticated functions. Among these are meta-scaffolds: structures designed to balance mechanical strength with the need to transport nutrients.

AI optimizes these internal architectures, allowing for the creation of flexible devices that can interact with human tissues without causing damage. Algorithms help explore bio-inspired designs that would be impossible to conceive with traditional methods, optimizing the internal shape to encourage cell adhesion. Furthermore, the use of adaptive materials allows for implants capable of changing shape or stiffness in response to stimuli like body heat or humidity. Managing this dynamism is one of the frontiers of modern medicine, where AI plays a key role in predicting these temporal transformations.

A new era for medicine

The ultimate goal of these technologies is clinical translation, the journey from the laboratory to the operating room. The integration of AI, bioprinting, and computational design is a new way of understanding health that is leading to prostheses and implants tailored to the anatomy of each individual.

This is the context of TENTACLE, a project funded by the European Union that aims to revolutionize the treatment of colorectal tract defects. The ambition of TENTACLE is to develop a 4D bioprinting platform integrated into endoscopic systems, allowing surgeons to intervene directly inside the body to repair lesions. To do this, researchers are employing cutting-edge technologies, such as the most advanced AI algorithms, to face this challenge.

Would you like to learn more about this topic? Read the scientific article “Roadmap on Artificial Intelligence-Augmented Additive Manufacturing“.